News 2024 part 1

We've had an amazing few days with so many interested visitors at our stand. Thank you all for your enthusiasm and support!

Excited for the final day ahead! 💪🏼

What a fantastic first Maritime Industry Day!

We had a lot of visits from (potential) customers and industry stakeholders. We're grateful for all the positive reactions and support.

Looking forward to the next two days and we're excited to welcome you to our stand L155.

Special Delivery to MTS Diff!

A brand new UTI, designed for fully closed, gas-tight measurements, including ullage, temperature, and interface (free water). This innovative tool is essential for precise quantity inspections and calibration of onboard radar systems, ensuring accuracy and reliability for oil owners and traders.

Thank you for your trust in our company and products.

Inland Shipping news!

Introducing the brand-new stainless-steel chemical tanker, MTS EQ! Crafted with precision by the skilled hands at BREKO Shipbuilding & Repair / PSI Piping, this impressive vessel measures 86 meters in length, 11.45 meters in width, and 3.70 meters in depth, with a deadweight of 2500 MT.

What sets MTS EQ apart is its smart 3-parcel line system, enhancing its flexibility for various industry needs. Additionally, our innovative closed vapour lock valve systems ensure completely closed and emission-free measuring and sampling inspections. And with each installation comes a demonstration for the crew.

Now under the expert management of Interstream Barging, MTS EQ is ready to embark on its voyages. A big thank you to everyone involved in bringing this vessel to life. We wish the crew countless safe journeys and seamless inspections!

This week, we're excited to announce the installation of yet another closed sampling system!

Allow us to introduce the MTS Temptation: 110 meters in length, 11.40 meters in width, and a voluminous capacity of 3000 M3. At SLK Shipping, their commitment to innovation extends beyond mere advancement. It's about safeguarding the health and safety of their crew, industrial partners and environmental responsibility. And as impending regulations prohibit open sampling, this investment underscores their proactive approach to compliance and excellence.

The butterwash hatches were collected and returned during her trip from Germany to Amsterdam, without causing any delays in the diligent TankMatch B.V. planning!

A big thank you to Klaas Leinenga and Popko Lamein for the trust in us and our product.

Dear Network,

We're attending the Maritime Industry event again (28, 29 and 30 May)! We'd like to welcome you at our stand L155.

For free registration: https://lnkd.in/em6JJsu6

Yesterday, we had the pleasure of visiting MTS Argonon to conclude the final stage of our assignment; a demonstration of closed inspection equipment. This part of our service is key in providing shippers and crew with a comprehensive understanding of the inspection process, its accuracy and the associated advantages it brings.

MTS Argonon from Deen Shipping made a significant size change! 4 additional cargo tanks have been incorporated and became even a bigger value for their customers. This impressive enlargement, handled by BREKO Shipbuilding & Repair / PSI Piping Hemiksem, includes:

- length extended from 110 to 135 meters

- number of cargo tanks increased from 8 to 12

- deadweight capacity boosted from 6060 MT to 8016 MT

Our gratitude extends to Deen Shipping for involving us in this remarkable project, and to Breko Hemiksen for the invaluable collaboration!

Yes, in the pocket!

Very proud we've achieved our ISO certification from DNV once again! This accomplishment underscores our unwavering commitment to quality, reliability, continue improvement, customer satisfaction, environment, health and safety for personnel.

We couldn't do this without the excellence from the Quality Department! Many thanks for the hard work and diligence in upholding these standards.

We have more barge news to share!

Meet MTS Detroit, a well-maintained ship with a length of 86 m, 9.6 m width and a deadweight of approx. 1650 MT. Recently she endured maintenance at spotless wharf the De Gerlien van Tiem Scheepsreparatie - Nieuwbouw. As CIMS Netherlands keeps updating and innovating their fleet, they used the opportunity to install our Vapour Lock Valves. This advanced system ensures fully closed inspections, an essential feature given the impending regulatory changes. It’s not only benefitting the health and safety of the crew, but it also increases precision for the industry. Accurate quantity determination and representative sampling are indispensable for oil owners

We extend our sincere gratitude to CIMS Netherlands for entrusting us with this significant assignment, and we eagerly anticipate future collaborations!

A brand-new inland ship with an amazing festive start!

Hats off to Volharding Shipyard Werkendam for crafting this masterpiece. Meet MTS Volharding 16, an impressive inland barge with a length of 110 meters, a width of 11.45 meters and a cargo capacity of 2931 tonnes. Fully equipped with the latest innovations the market has to offer! For example, she’s equipped with Tank-Eye B.V.’s advanced closed gauge and sample solutions comprising gas-tight valves from Honeywell. Ensuring full readiness for all closed measurements (e.g. gasses, obq, rob, ullage, free water, temperatures) and closed sampling (e.g. first foot, upper, middle, lower, absolute bottom and running).

A special thank you to VARO Energy for their unwavering support and commitment to enhancing health and safety standards. We also express our sincere appreciation to DARI Volharding Group for entrusting us with yet another magnificent assignment and for inviting us to celebrate this milestone. To the crew of MTS Volharding 16, we wish you endless safe closed inspections as you embark on this exciting chapter!

It was truly a pleasure to work with Joris Croes & Jochen Reynaert from Versotrans!

Their dedication to excellence was evident as we worked together at Offshore Ruijtenberg on enhancing one of their impeccable tankers. With their innovative approach, they chose our vapour lock valves to ensure increased health & safety for crew and surveyors, as well as enabling the most accurate fully closed gauge and sample inspections for the charterer.

Introducing MTS Kaminastad, a stainless-steel tanker dimensions of 85m in length, 10.5m width, and 1700 MT deadweight. Serving the chemical inland shipping market, TankMatch B.V. is proud to play a crucial role in its planning and operations.

We extend our heartfelt gratitude to Versotrans for placing their trust in Tank-Eye B.V. for this important assignment.

Introducing our latest innovation;

the specially designed closed gauge / sample equipment backpack, crafted to revolutionize surveying operations on barges and shore tanks.

In collaboration with local surveyors, we've engineered this backpack with utmost precision to enhance safety and ergonomics for professionals in the field.

* Constructed from robust, lightweight, anti-static, and fire-retardant fabric, ensuring durability without compromising on comfort.

* Compatible with any brand or type of inspection equipment.

* Streamlined design featuring an integrated backpack system for convenient carrying, allowing surveyors to move freely and effortlessly.

* Equipped with an internal back protector shield, safeguarding surveyors against potential risks during operations.

* Wear-resistant plastic reinforcements on the corners provide added resilience, extending the lifespan of the backpack even in demanding conditions.

* Multiple handles strategically placed for easy handling.

At Tank-Eye B.V., our commitment is to serve the industry with innovative solutions that elevate standards and drive excellence.

A custom-made solution for MTS Ailena!

When transporting multiple small parcels and having trim and/or list, a reference point exactly in the middle of the tank is crucial. There is where we step in!

In a close collaboration with NAVIGLOBE, the shippers, the notify body, shipyard Nieuwenhuijsen Scheepsbouw and Kalibra International B.V., we've devised an innovative solution tailored to meet the unique needs of MTS Ailena. Where generaly is the tank head the middle of the tank, this time, we've placed it on deck level for optimal performance. We extend our gratitude to all parties involved for their seamless cooperation, ensuring a successful outcome. It's rewarding to know that everyone is pleased with the final result.

Here's to smooth sailing and accurate closed inspections for the crew ahead!

Marking a special moment when a new barge, MTS Fiducia, is released for service.

From speeches to emotions and sheer happiness describe the momentous occasion. Honoured to witness and celebrate this moment with the Bosman Shipping Group team and involved stakeholders.

Introducing the magnificent MTS Poros, a brand-new bunker tanker. With dimensions: 135m in length, 17.5m in width, and an impressive deadweight of approximately 9KT, she's serious valued add to the demanding Fuels and Feedstocks market!

But what truly sets her apart? V-SHIPPING made the smart call to ensure she's methanol bunkering ready, making her a perfect fit for the future of maritime fuel. Paired with our innovative Vapour Lock Valve, which enables closed/gastight gauge & sample inspections, she's ready for any challenge.

We would like to use this opportunity to:

- thank V-SHIPPING for entrusting us with this beautiful assignment

- compliment Den Breejen Shipyard for their exceptional craftwork

- wish Victrol all the best with scheduling her voyages

- wish the crew countless safe journeys and successful operations ahead

Yet another successful assignment accomplished!

This time we’ve served not only an innovative shipper, but quite a big Red Bull Racing & Red Bull Technology fan: Chris Moeliker from Tankvaart Diff bv! MTS Diff, a spotless and fully up-to-date tanker measuring 86 m in length, 9.6 m width and a tonnage of approx. 1700 MT.

The process unfolded seamlessly:

- Together we identified the optimal location on the tankhead.

- The welder from Scheepswerf Gebroeders Kooiman B.V. expertly welded the flange and drilled the hole.

- Henri Vranken, representing Tanktech, recalibrated the reference point and generated new tank tables.

- Tank-Eye B.V. provided an insightful demonstration on fully closed gas, obq, rob, ullage, temperature, free water measurements and how to sample any level.

ANACO BV welcomed her back into the fleet, they thoroughly oversee her scheduling to ensure optimal trip management.

Many thanks for entrusting us with this assignment!

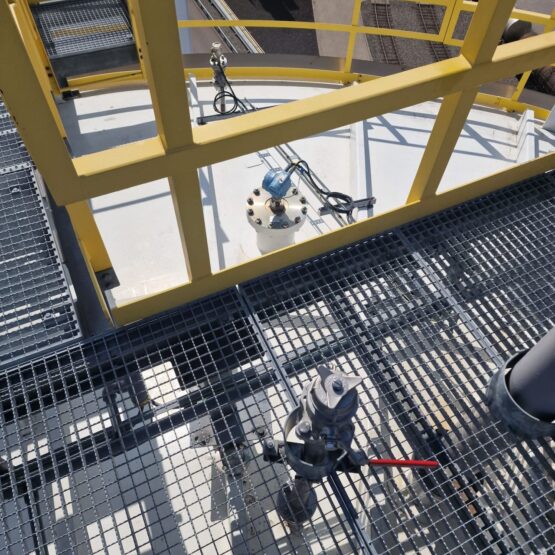

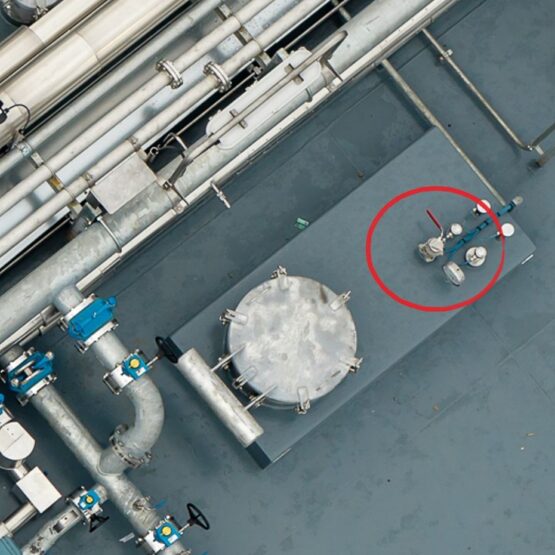

Excited to unveil our latest breakthrough!

From closed barge tanks to closed shore tanks, marking a significant advancement in our services. Following successful trials, we're thrilled to introduce our custom-made solutions for closed and gas-tight inspections atop shore tanks.

What are the possibilities?

Closed multi-level sampling; absolute bottom, first foot, running and spot (e.g. upper, middle, lower)

Closed gas measurements; Oxygen, Nitrogen, LEL etc.

Closed water dipping before draining

Closed dipping on emptiness (OBQ / ROB)

Closed temperature measurements

What are the advantages with this innovative approach?

Health and Safety: No more unhealthy situations, emissions, and unpleasant stench during sampling.

Environmental Impact: Eliminate the need for unnecessary nitrogen purging, reducing environmental footprint.

Swift and Economical: Our solution closes off shore tanks rapidly and at a fraction of the cost compared to alternative systems.

Curious to learn more? Don't hesitate to reach out. Let's discuss how these advancements can revolutionize your operations.

And the first Surveyor is...... Saybolt International!

Together, we're taking a proactive step towards enhancing our services by providing comprehensive training material and sessions for both personnel and clients on closed measuring and sampling inspections.

Also interested? Please contact us.

Let the Maritime Innovation Platform begin!

MTS Eurostar endured a significant transformation at Scheepswerf Drechtsteden.

Beyond routine repairs she fully recoated all cargo tanks! Quite an intense job considering her sizes: LOA 135 m, 17.25 m width and can carry approx. 8.6KT! Eurostar Shipping V.O.F ‘s unwavering commitment to innovation, did not hesitate and used the timing to install the Tank-Eye B.V. closed gauge and sample system comprising gas-tight valves from Honeywell as well. This proactive approach aligns perfectly with the upcoming rules and regulations, where open measuring and sampling belongs to the past for a width range of products. Here is where we offer the solution by enabling all inspections while cargo tanks remain closed!

Now she’s fully equipped to resume operations under the strategic guidance of Trendco BV.

A big thank you to Olivier Timmermans and Hendrik Jan van Dodewaard!

Bosman Shipping Group keeps expanding!

TeamCo Shipyard showed its excellence by delivering this challenging project; MTS Fudicia. With a LOA of 135 m, 11.45 m wide and approx. 3800 MT deadweight spread over 11 cargo tanks, she'll be an outstanding addition to the inland shipping market.

Thanks to Bosman Shipping Group's committed support, we're honoured to contribute to their impressive tanker. Ahead of completion, we united the crew for a demonstration of their new gauge and sampling system, showing closed gas measurement, ullage monitoring, temperature control, free water detection, and closed multi-level sampling. STETRA Gesellschaft für Schifftransporte mbH welcomes her with open arms and commits planning her voyages with care and precision.

Many thanks for the assignment and wishing the crew countless safe passages!

Again dolderman showed its building skills as project MTS Noa has come to a successful end!

She measures 110 meters in length, 11.45 meters in width, a deadweight of approximately 2650 MT spread over 9 cargo tanks and will sail under the Bosman Shipping Group flag. Burando Barging will take her under their wing and deploy her to the fullest for the transportation of various products.

The cargo tanks are installed with vapour lock valves, which offers the option to closed inspections like gas (LEL, UEL, Nitrogen, Oxygen etc.), obq, rob, ullage, temp, free water and multilevel sampling (first foot, spot, running and absolute bottom). An absolute must have for closed, accurate, representative and independent inspections.

We want to thank Bosman Shipping Group for another beautiful assignment and wishing the crew countless safe passages.

A custom made Tank-Eye B.V. tankhead for expo and training purposes, with thanks to Willems Boven-Leeuwen Piping & Equipment and the finishing touch from Dockmarks Signs, geat job guys 🙏!

Let the Open Scheepvaartdagen Antwerpen begin! Happy to welcome you in our stand.

Thankful for yet another rewarding assignment!

Meet the impeccably maintained inland tanker MTS Cosmos with a LOA of 85 m, 9.5 m width, a deadweight of 1705 MT and proudly belonging to the ANACO BV fleet. While undergoing maintenance at BREKO Shipbuilding & Repair / PSI Piping, shipper Stevens Karel used the moment to enhance the vessel's capabilities by installing a new Tank-Eye B.V. closed gauge and sample system comprising gas-tight valves from Honeywell.

On Monday we jointly determined the best location of the Vapour Lock Valve installation, pinpointing the middle of the tank as the preferred spot. The welder commenced welding and drilling activities on Tuesday. Wednesday Tank-Eye B.V. gave a demonstration to the crew, and Henri Vranken (Tank-Tech) determined the new reference point with his special 3D lidar scanner. The entire process unfolded seamlessly!

MTS Cosmos now proudly joins the fully closed fleet, ensuring emissions are contained on board during measuring and sampling inspections.

A sincere expression of gratitude goes out to Mr. Karel Stevens and Anaco BV for entrusting us with this assignment and their confidence in our product.

We'd like to extend our deepest gratitude to our network for surpassing 1500 followers!

VARO Energy continued its collaboration with their trusted partner Interstream Barging Netherlands B.V.

MTS Arne - with dimensions 86 meters in length, 10.6 meters width, a deadweight of approx. 1750 MT – was scheduled for class certification at Nieuwenhuijsen Scheepsbouw BV. The perfect timing for maintenance and other improvements!

Having health, safety, and the environment as highest shared commitment, VARO and Interstream jointly invested in several upgrades to meet the latest standards. A crucial aspect of this project involved the implementation of a closed gauge and sampling solution comprising gas-tight valves from Honeywell, proudly supplied by Tank-Eye B.V.

We had the privilege of presenting this innovative and emission-free solution to the owners and the entire crew, highlighting the usage and benefits of closed inspection equipment. The collaborative demonstration was received with enthusiasm and engagement, and we express our gratitude for the warm welcome extended to our team.

A sincere expression of gratitude for placing your trust in Tank-Eye for this important assignment. Here's to closed gas tight inspections and the beginning of a new chapter with MTS Arne!

Our collaboration continued!

Jelle Mathon started at Rijnaarde Global Trading & Logistics BV and set ambitious goals by making substantial investments in a safer and environmentally friendly fleet. In our latest project, the spotlight is on MTS Silke from Ruijven B.V., chartered by Rijnaarde, which recently endured class certification at Scheepswerf en Machinefabriek 't Ambacht B.V.

Various enhancements were implemented to prioritize safety and reducing emissions. One of the key upgrades involved; installing tank head vapour lock valves. The careful process included selecting the perfect location, followed by a precise drilling and welding operation. The result? MTS Silke is now fully equipped for all closed inspections including gas, ullage, temperature, water, and multi-level sampling. This ensures that harmful emissions remain contained, benefiting not only the crew but also surveyors, terminal personnel, and the environment. The MTS Silke is now prepared for Rijnaarde's liquid bulk transports, where unnecessary emissions are no longer a concern.

We extend our sincere gratitude to Rijnaarde & Ruijven for entrusting us with this important project. Looking ahead, we're excited about the prospects of a long-term collaboration that aligns with our shared commitment to environmental responsibility. Here's to a safer and cleaner future!

Latest Tank-Eye update!

We had the pleasure to visit TeamCo Shipyard where they are working on their latest masterpiece - the magnificent tanker MTS Beethoven! With an imposing length of 135m, a substantial width of 17.5m and a deadweight of approximately 8725 MT, MTS Beethoven is ready to set sail and make waves into the maritime ARA region.

Tank-Eye B.V. proudly played a small role in the final stages, ensuring the implementation of a state-of-the-art closed gauge and measurement system comprising gas-tight valves from Honeywell. As a part of the service, our team had the privilege of presenting this innovative solution to the owners and the entire crew. Grateful for the warm welcome and engagement during this collaborative demonstration. Dutch Barging Services BV will now embrace her into their fleet, guiding and accurately planning her journeys under their expert care.

A heartfelt thank you to MICHAND for entrusting Tank-Eye B.V. with this significant assignment. Here's to smooth sailing, harmonious voyages, and the beginning of a new chapter with MTS Beethoven!

We proudly announce the latest addition to our closed systems fleet - the brand new MTS Audenda, owned by Gouke Leeuwestein at Audenda Shipping B.V.

Measuring 110 meters in length, 11.45 meters in width, and a deadweight of approximately 2630 MT spread across 8 cargo tanks, MTS Audenda is a true example of engineering and design. Compliments to BREKO Shipbuilding & Repair / PSI Piping and Den Breejen Shipyard who jointly guided the construction process including the vapour lock valve installation. Afterwards Tank-Eye B.V. demonstrated the fully closed gas, obq, rob, ullage, temperature, free water and sampling equipment.

Now she’s in the professional hands of TankMatch B.V. who’ll carefully schedule her voyages. We’d like to thank you all for this assignment and wish Gouke and the crew innumerable safe voyages!

Busy times at Tank-Eye B.V., but it's even more impressive to witness how dolderman is effortlessly managing the continuous workload! Another magnificent project is slowly making space for the next one.

We're referring to the beautiful tanker MTS Norma, where father and son Grinwis from Dancha Riverline have tirelessly worked on for the past months. We're grateful that they've chosen Tank-Eye B.V. for gauging and sampling solutions, comprising gas-tight valves from Honeywell. Their decision reflects a commitment to health and safety for everyone on board, promoting an emissionless, representative, and independent gauge/sample system. With her colossal dimensions of 135m in length, 17.5m in width, and an impressive 8725MT deadweight, MTS Norma emerges as a substantial asset to the ARA inland shipping market. She's entering the Trendco BV fleet, where they've got the scheduling covered with expertise.

Using this opportunity, we express our sincere appreciation to the Grinwis family for entrusting us with this significant assignment. Here's to countless safe voyages and thorough closed inspections!

Dynamic energy at Asto Shipyard and working tirelessly on another imposing project! Proud to introduce the impressive tanker, MTS Veloma, having a length of 125m, 17.5m width, and a robust deadweight of approximately 8725 MT. She’ll be soon gearing up for extensive transports in the ARA region.

In the final stages of the venture, Tank-Eye was present, showcasing the closed gauge and measurement system to owners Patrick Mandemaker, Linda Mandemaker and the crew. Grateful for the warm welcome aboard and the attentive engagement during the session. Appreciate the collaboration.

Many thanks to Mr. and Mrs. Mandemaker for trusting us with this assignment. Wishing them and the crew safe and enjoyable voyages ahead!

Dolderman is on the role, yet again an impressive project has come to an end! Introducing MTS Lars with a length of 125m, 17.5m width and a deadweight of approx. 8725 MT.

With Bosman Shipping Group strongly supporting our system, we are proud to be a small addition of this expansive tanker. Just before completion of the whole project we gathered with the crew for a demonstration of their brand-new system and showing; closed measuring of gas, ullage, temperature, free water and closed multi-level sampling.

We’d like to thank Bosman Shipping Group for their continuous support and wishing the crew countless safe voyages and closed inspections!

Last week, we had the pleasure of visiting MTS Bauke at BREKO Shipbuilding & Repair / PSI Piping, where we’re warmly welcomed on board by shipper Bert Langius.

Once the Vapour Lock Valve installation completed, the Tank-Eye B.V. team demonstrated the efficiency and precision of closed multi-level sampling and measuring gas, ullage, temperature and free water.

We wish Bert Langius and his crew countless closed inspections ahead!

Are you a ship owner with upcoming maintenance or class certification? And are you considering our closed measurement and sampling system? Now it's the time!

First, we determine together the best position on the tank head. Once your tanks are gas-free and approved for hot work, the welder can get started. Within a day, the drilling/welding work is done, and the system is installed. Afterward, the calibration bureau (Henri Vranken from TankTech or Kalibra Oil and Gas Services) determines the new reference point and prepares new tables. That's it!

After this process, your ship is ready for all closed inspections without having to release pressure, meaning no unwanted emissions and harmful vapours on board. Gas measurement, liquid level determination, temperature assessment, free water sounding, and sampling at any desired level have never been so healthy and safe!

Feel free to contact us for an appointment, presentation, and demonstration. It's interesting, informative, and, of course non-binding.

Isn’t she magnificent?! With 135 metres in length, 17.5 meters width and deadweight of +/- 8.5KT she’s a impossible to miss; meet MTS Tricolore.

Mr. Richard Driessen from Driemaas Shipping led the full construction in close cooperation with shipyard Oonincx Scheepsonderhoud to a successful end. We take pride in being a modest contribution to this impressive project. Now she’s ready for duty and will join the UniBarge fleet.

We’d like to thank Richard Driesen for the assignment and the trust in our product. Here’s to countless safe voyages, closed gauging and sampling inspections 🥂!

Introducing MTS Archelle, 85 m in length, 9.6 m width and a deadweight of approx. 1500 MT. During her intermediate class certification Asto Shipyard, she integrated innovation and installed the Tank-Eye B.V. gauging and sampling solutions comprising gas-tight valves from Honeywell.

The driving force behind this upgrade? The owner's commitment to SAFETY. Now he can keep his cargo tanks closed during sampling, measuring, and gas testing. To safeguard the crew, surveyors, and terminal operators from direct exposure to product vapours, ensuring a safer and healthier work environment.

With more ports and terminals enforcing restrictions on manually opening cargo tanks for measuring and sampling, the need for reliable closed inspections increases. The Vapour Lock Valves have proven to be the game-changer, eliminating sample contamination plus the risk of outturn losses.

Congratulations to Bosman Shipping Group and dolderman for another impressive project!

MTS Julia, measuring 110 meters in length, 11.45 meters in width, having a deadweight of approx. 2850 ton, is a valuable addition to the inland shipping industry. We're proud to have installed the Tank-Eye B.V. gauging and sampling solutions comprising gas-tight valves from Honeywell, ensuring readiness for full closed quantity & sampling inspections. Enhancing accuracy while guaranteeing vapour-free, safer and healthier work environments.

Grateful for the opportunity to contribute and wishing the crew enduring health and safety on their journeys!

Another fantastic job done by Dockmarks Signs 👌

Thanks guys!

Inland shipping news!

Another valuable ship has entered the inland shipping sector! Meet MTS Chaser; part of the remarkable TankMatch B.V. fleet, 110 m in length,11,45 m width and a deadweight of approx 2630 MT spread over 8 cargo tanks. Compliments to Asto Shipyard who steered the entire construction process including the Tank-Eye B.V. Vapour Lock Valves installation. Ensuring readiness for all fully closed measurements (e.g. gasses, obq, rob, ullage, free water, temperatures) and sampling (e.g. first foot, upper, middle, lower, absolute bottom and running).

We’d like to extend our gratitude to TankMatch B.V. and Asto Shipyard for the trust in our company and products!

Contact

Do you want more information about Tank-Eye? Send us an email and we will contact you shortly.

De Noordkade 28

3341 SZ Hendrik-Ido-Ambacht

The Netherlands